AV-1 MASS AIRFLOW MEASUREMENT SYSTEM

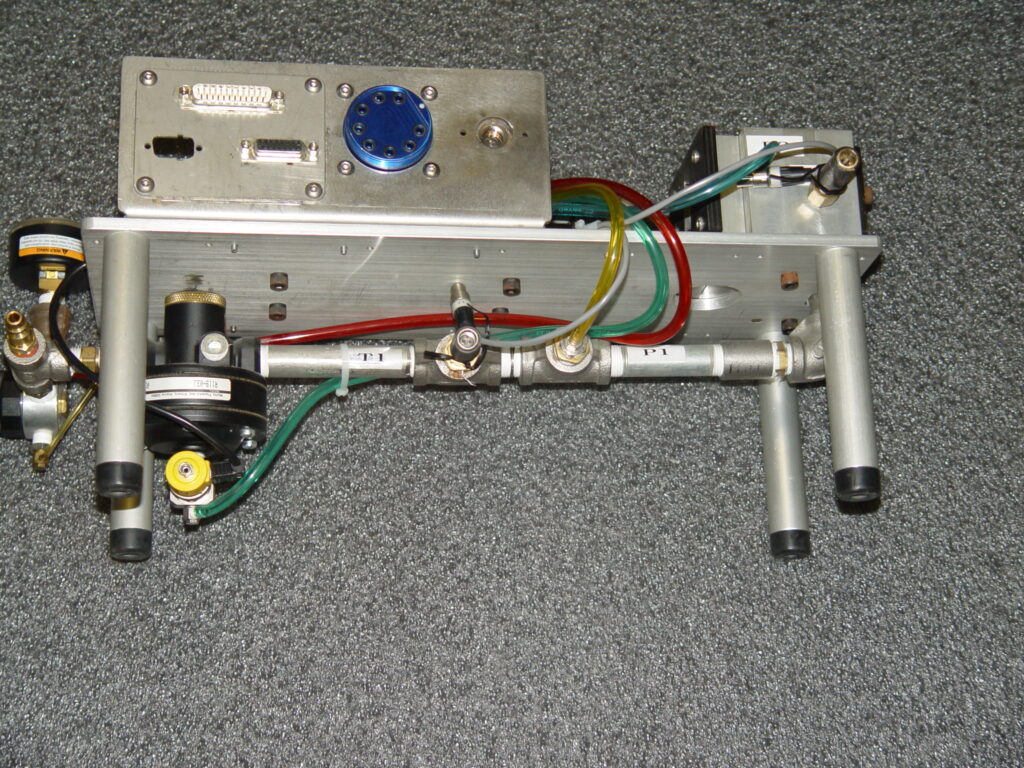

The AV-1 is a high-precision system for measuring mass flow of air specifically designed for the use in the gas turbine industry. It also uses shop air to produce measurements. The Instrument Cabinet is modular and compatible with the AF16. It can be effectively coupled with the AF16 to provide a wide range of test parameters.

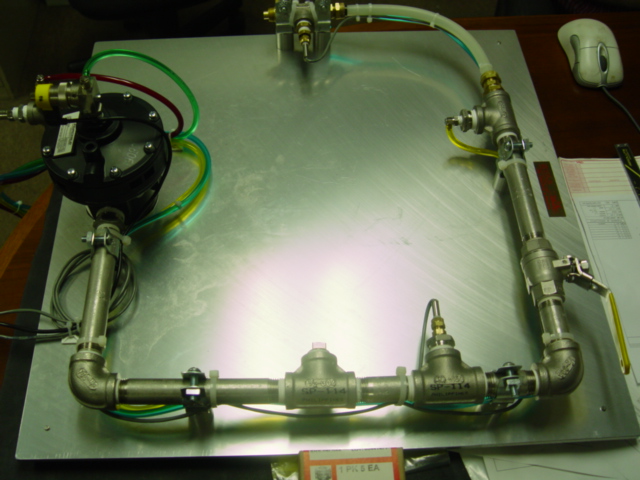

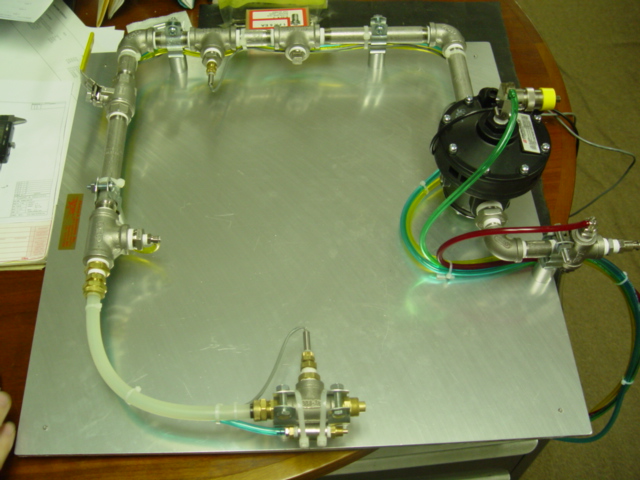

The purpose of the AV1 Mass Airflow Measurement System is to determine the total airflow of various components such as gas turbine nozzles, nozzle segments, wheels, combustion liners, and other similar components. This is measured from airflow pressure differentials, and is accomplished by the AV1 channeling air over and/or through the test component, which leads to the determination of the airflow area for the component being inspected. The AV1 has been designed, with the necessary flexibility to measure a variety of components.

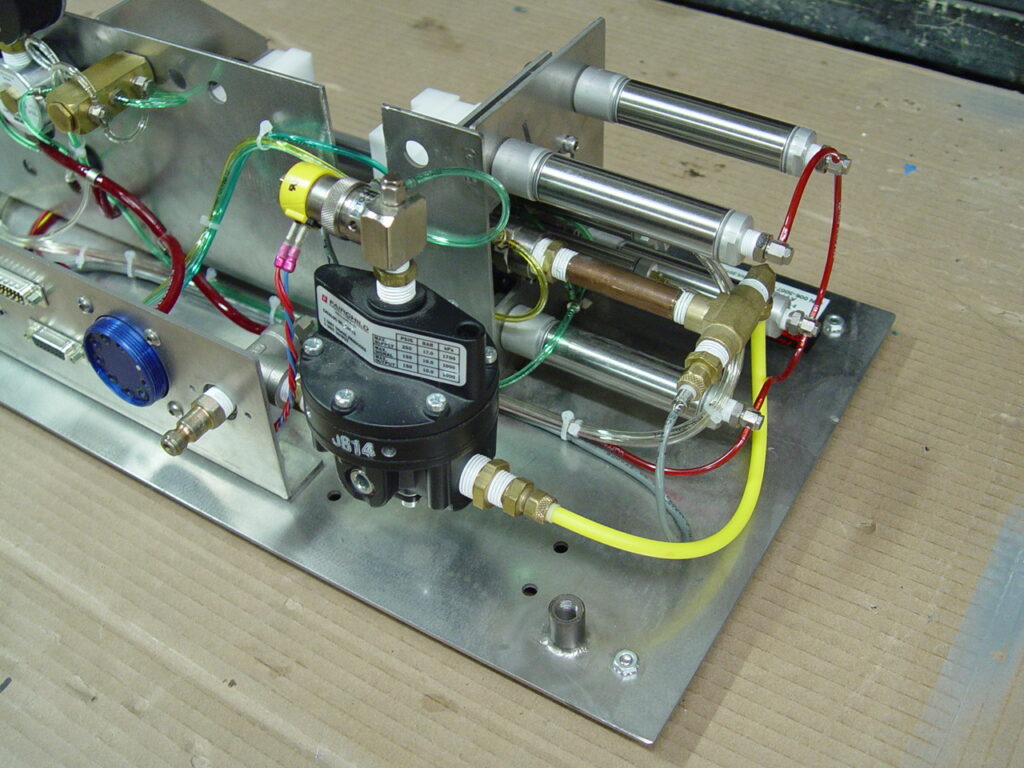

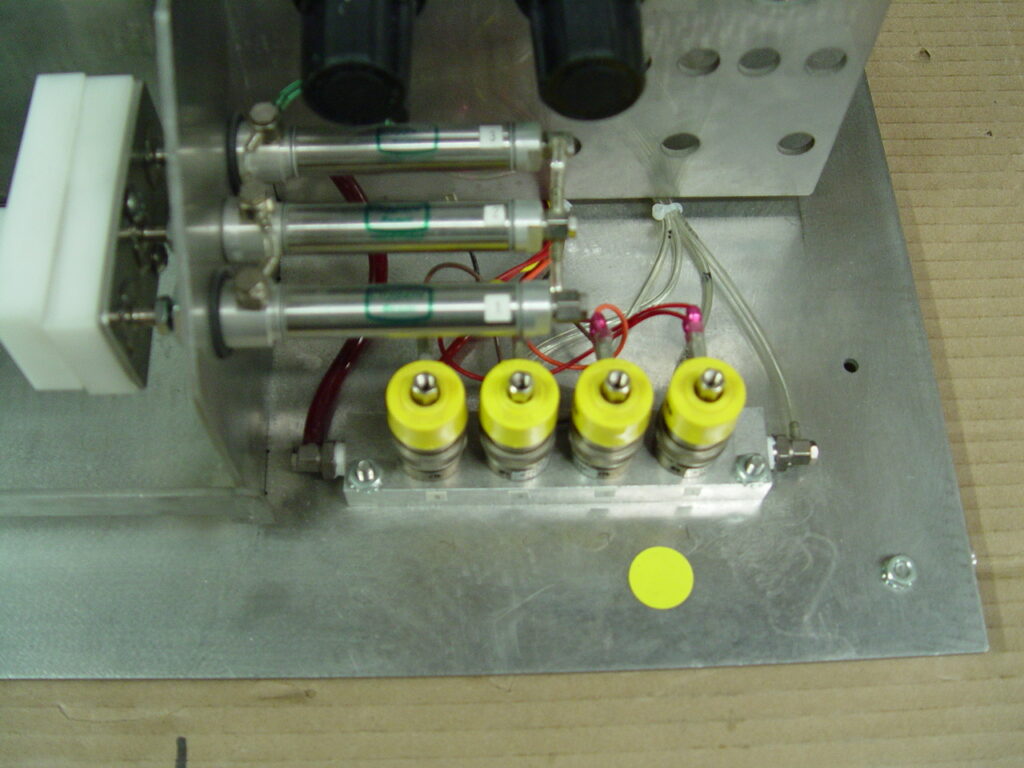

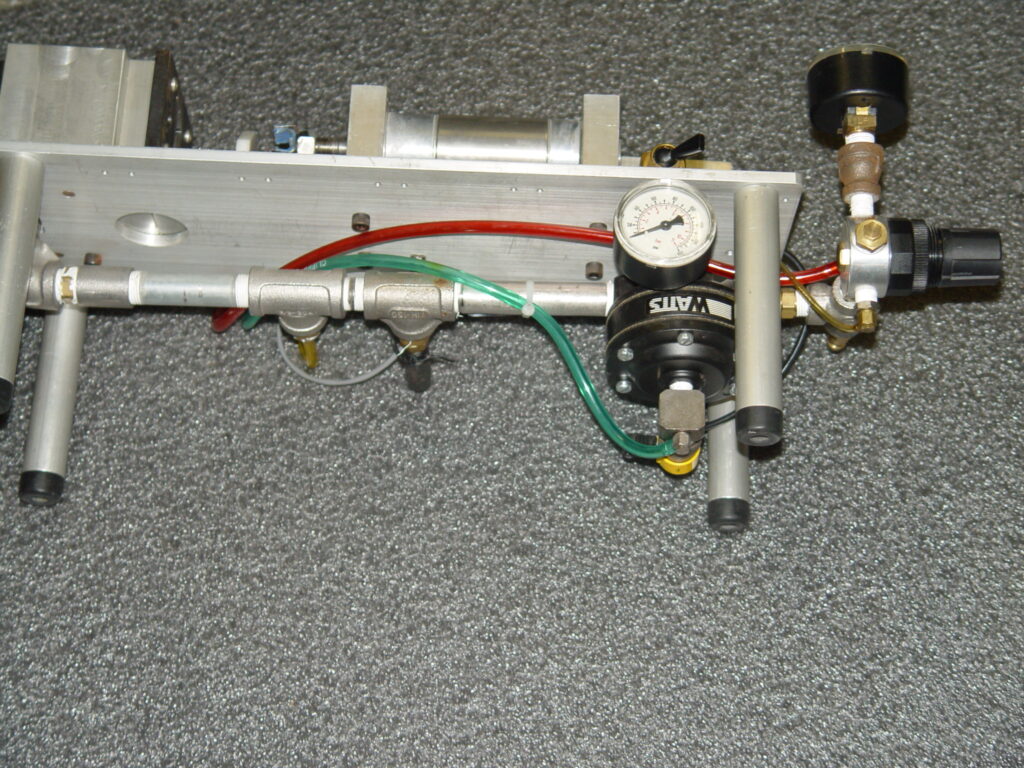

Mass airflow is obtained by utilizing a calibrated sonic nozzle positioned upstream (i.e. in series with) of the fixture and component being evaluated. A separate port located on the fixture is used to sense the actual pressure at the part. A regulator is used to adjust the pressure upstream of the sonic nozzle, which in turn varies the P3 Part Pressure. Once the required P3 Part Pressure is obtained the operator waits until the mass flow rate meter has stabilized and then records the reading.

The AV1 has a modular design, and the instrument cabinet is compatible and can also accommodate and is used in tandem with the Fleming AF-16S Airflow Measurement System. The AV1 has computerized readout and controls via a personal computer with Fleming Software. Electronics and instrumentation is supplied in a cabinet separate from the meter-run. The instrumentation cabinet is approximately 16″ x 18″ x 7″, and the instrument cabinet is interfaced to a computerized control system proved with the equipment.