AF16-S Airflow Measurement System is one of Fleming & Associates newest products.

This redesign of older shop air machines eliminates operator errors and improves reliability. It also has a quicker measurement cycle than AF36.

The purpose of the AF16-S is intended for measuring areas under 10 square inches of various components such as gas turbine nozzles, nozzle segments, wheels, combustion liners, and other similar components. The area is measured from airflow pressure differentials. This is accomplished by the AF16-S channeling air over or through the test component that leads to the determination of the airflow area for the component being inspected.

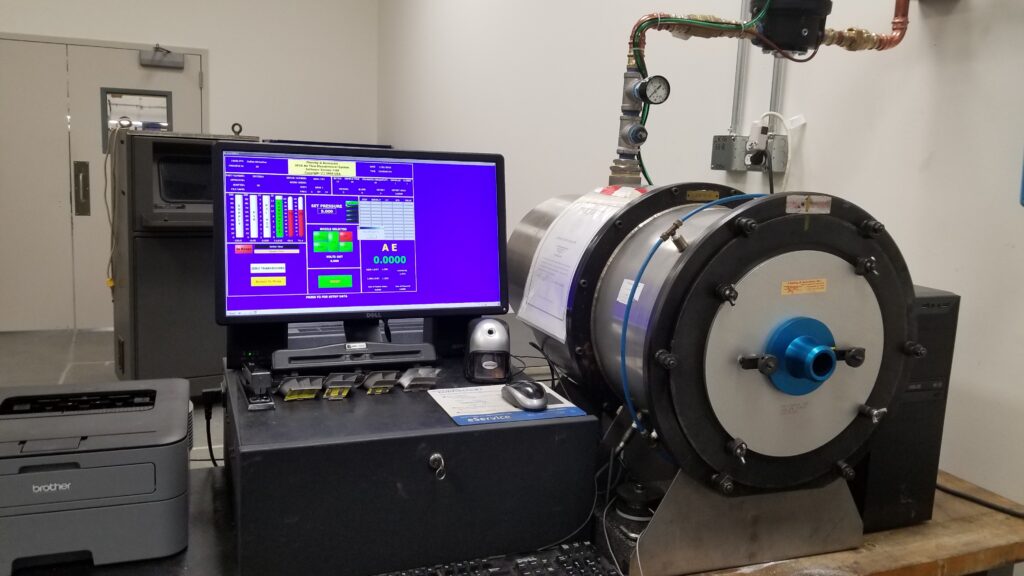

The entire system can be placed on a standard workbench.

The AF16-S uses a sonic nozzle (venture) to control mass flow. There are actually five Sonic Nozzles in the AF16-S, each one to be used for measuring a different area range. The Sonic Nozzle is used to measure mass flow into the main plenum.

The part’s area is determined by the mass flow (pounds per second through the sonic nozzle) required to achieve the specified pressure in the main plenum. Fast and flexible, the AF16-S can be configured to measure EFA or mass flow.

The Control Software supports automated correlation to linear or non-linear measurement units.

The AF16S is a great, low-cost alternative for high production facilities. Tooling (Adaptors) mounts the same as the AF36.

The AF16-S operates on shop air and 120/240 VAC, but is otherwise self-contained. Due to its short cycle time, the AF16-S is especially suited for obtaining area measurements of components such as nozzle segments in a high production environment.

The AF16-S system’s basic components consist of a plenum chamber, and instrument cabinet and a computerized system controller. The instrument cabinet may also be used in tandem with the Fleming AV1 Mass Airflow Measurement System.

The entire system can be installed on a standard 36″ x 72″ (91.4 x 183 cm) workbench.

Shop air supply flows through a control valve into the supply plenum. The air then enters a sonic nozzle (venture) which discharges into the main plenum and thus through the component being measured. A ball valve is provided enabling complete shut-off. The control valve regulates the pressure in the sonic nozzle’s supply plenum. The computerized control system controls the pressure in the main plenum automatically. The component’s area is determined by the mass flow through the sonic nozzle required to achieve the specified pressure in the main plenum (upstream of the component). The use of Sonic Nozzles can provide another method of trace ability. The control software supports automated correlation to any linear and many non-linear measurement units.

The chamber size is 14.8″ (35.6 cm) diameter by 18″ (45.7 cm) long, with mounting for 12” (30.5 cm) and 16” (40.6 cm) outside diameter flanged adaptors (11″ [27.9 cm] and 15″ [38.1 cm] openings).

The AF16-S has the same mounting for adaptors as the 12″ (30.5 cm) and 16″ (40.6 cm) diameter mounting rings for the Fleming AF36 Airflow Measurement System. Hook clamps, used to hold fixtures, are a convenient and efficient method of mounting. An O-ring on the face of the mounting makes a reliable and durable seal between the plenum and the adaptor. Baffling assures good flow distribution in the plenum.

The AF16-S has computerized readout and controls via a controller system with Fleming Software. Electronics and instrumentation is supplied in a cabinet separate from the plenum chamber. The instrumentation cabinet is approximately 16″ x 18″ x 7″ (40.6 x 45.7 x 17.8 cm). The instrument cabinet is interfaced to a controller provided with the equipment. The instrument cabinet is compatible with and can be used in tandem with the Fleming AV1 Mass Airflow Measurement System

Adaptors are required for seating the component to be measured onto the AF16-S, and channeling the air smoothly into the component being measured. An easy-to-change mounting ring allow for a range of adaptors. Many adaptors are already available, and adaptors for most components can be furnished with the equipment or ordered at any time