The main PRODUCT of our company is the Airflow Measurement Systems.

Fleming & Associates Calibration, Inc. is a pioneer in Dynamic Airflow Measurement techniques and become a worldwide leader of Airflow Measurement Equipment. Based on the benefits of Aerodynamic Measurement our Company objective: to serve and support the Aerospace Industry with the most reliable and efficient Airflow Measurement Equipment and Adaptors available today.

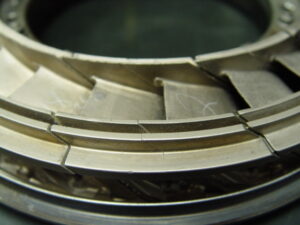

A gas turbine is a rotary engine that extracts energy from a flow of combustion gas. It has an upstream compressor coupled to a downstream turbine, and a combustion chamber in between. Energy is added to the gas stream in the combustor, where air is mixed with fuel and ignited. Combustion increases the temperature, velocity and volume of the gas flow. This is directed through a nozzle over the turbine’s blades, spinning the turbine and powering the compressor. Energy is extracted in the form of shaft power, compressed air and thrust, in any combination, used to power aircraft, generators, ships and trains.

When gas turbine engines are manufactured, overhauled, repaired or rebuilt, it is critically important to be able to measure the airflow through and over the various components of the engine to insure proper operation. Such measurements are made primarily on the nozzles and turbine vanes. Such testing and adjustment is critical to insure proper engine performance, and until 1950 all measurement was done mechanically. There are various ways of measuring such airflow mechanically, but the only industrially efficient way to do so dynamically is with Fleming & Associates Calibration, Inc. products, such as the AF36 Airflow Measurement System.

AERODYNAMIC MEASUREMENT was applied by August E. “Gus” Fleming in the late 1950’s when an unexpected problem arose that could not be solved by conventional means and it was found that a gas turbine nozzle warped so badly during engine testing that the traditional mechanical testing tools used to measure and adjust the nozzle would no longer fit onto the part. So August E. “Gus” Fleming, developed a new, Dynamic Airflow Process to determine the aerodynamic area of the nozzle, and other such gas turbine components. The improvement in the accuracy and speed of testing obtained by using this dynamic process was so great that test procedures on gas turbine components were changed to take full advantage of this methodology. This led to the development of the AF16 Test Bed and AF36 Airflow Measurement System, as well as various Adaptors to allow a variety of gas turbine components to be tested on the System. The AF36 has been continually refined since that time and is today the state of the art in Aerodynamic Measurement of gas turbine components

The primary advantages of airflow testing over mechanical gauging are that airflow measuring requires only a small fraction of the time required to gauge a component mechanically, and avoids the expense of calibration and repair of gauges. It should also be noted that historically, when mechanical gauging results do not agree with Effective Flow Area (EFA) test results produced with the AF36, EFA results provide a better indicator of engine performance.

It’s easy and reliability to determine the aerodynamic area of various components such as gas turbine nozzles, nozzle segments, wheels, combustion liners, and other similar components using Fleming Airflow Measurement Equipment. The area is measured dynamically through transfer standards, air pressures, temperatures and blower speeds. This is accomplished by the system adjusting blower speed to obtain the desired differential pressure across the component being measured, and then calculating the area as a function blower speed and the other above measurements.